The Role of Industrial Ovens in Quality Assurance for Construction Materials

In the realm of construction materials, ensuring quality is paramount. This is where the role of industrial ovens becomes crucial. These specialized ovens play a vital part in the quality assurance processes for various construction materials, including aggregates, asphalt, and concrete. This article delves into the significance of industrial ovens, their applications, and how they contribute to precision and reliability in material testing.

The Significance of Quality Assurance in Construction Materials:

Quality assurance is the backbone of any construction project. It involves a series of systematic processes to ensure that the materials used meet the required standards and specifications. This is not only essential for compliance but also for the longevity and safety of structures.

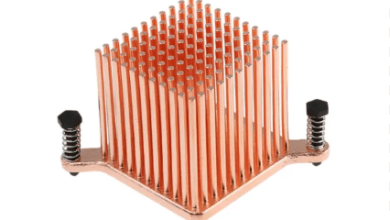

Understanding Industrial Ovens:

Industrial ovens are sophisticated pieces of equipment designed to meet the demanding needs of various industries, including construction materials testing. They come in different types, each tailored to specific applications. Key features such as temperature control, uniform heating, and safety measures make them indispensable in a laboratory setting.

Types of Industrial Ovens:

There are several types of industrial ovens, each catering to specific needs. Common types include convection ovens, vacuum ovens, and infrared ovens, each offering unique advantages in the realm of materials testing.

Key Features and Specifications:

Industrial ovens boast features like precise temperature control, even heat distribution, and advanced safety mechanisms. These features are crucial for achieving accurate and repeatable test results.

Industrial Ovens in Material Testing:

Material testing is a meticulous process that demands precision and reliability. Industrial ovens play a pivotal role in this domain, contributing to the accuracy and consistency of test results.

Uniform Heating for Accurate Results:

One of the key contributions of industrial ovens is their ability to provide uniform heating. This ensures that the materials undergoing testing experience consistent conditions, eliminating variables that could affect the accuracy of results.

Ensuring Compliance with Standards:

Construction materials must adhere to specific standards and regulations. Industrial ovens facilitate compliance by creating controlled environments for testing, ensuring that materials meet the required specifications.

Applications in Construction Materials:

Industrial ovens find diverse applications in the testing of construction materials, proving their versatility and indispensability in the field.

Concrete Curing:

Proper curing is vital for the strength and durability of concrete. Industrial ovens create ideal curing conditions, accelerating the process without compromising the integrity of the material.

Asphalt Aging Studies:

Asphalt aging can impact its performance over time. Industrial ovens allow for accelerated aging studies, providing insights into the long-term behavior of asphalt under different conditions.

Aggregate Drying and Analysis:

Aggregates are a fundamental component in construction materials. Industrial ovens are used for drying aggregates and conducting various analyses to ensure their quality and suitability for specific applications.

Benefits of Using Industrial Ovens:

The utilization of industrial ovens in material testing brings forth a multitude of benefits, contributing to the overall efficiency and reliability of the testing processes.

Precision and Consistency:

Industrial ovens create a controlled environment, ensuring that the testing conditions remain consistent. This precision is crucial for obtaining reliable and repeatable results.

Time and Cost Efficiency:

The accelerated processes facilitated by industrial ovens not only save time but also contribute to cost efficiency in the long run. Quick and accurate results enable faster decision-making in construction projects.

Enhanced Safety Measures:

Safety is a top priority in any laboratory setting. Industrial ovens come equipped with safety features, including temperature controls, alarms, and fail-safes, minimizing the risks associated with materials testing.

Choosing the Right Industrial Oven:

Selecting the appropriate industrial oven is a critical decision that impacts the accuracy and efficiency of materials testing. Several considerations come into play when choosing the right oven for specific applications.

Capacity and Size Considerations:

The size of the industrial oven should align with the scale of materials testing. Ensuring that the oven has adequate capacity for the intended workload is essential for maintaining efficiency.

Temperature Range and Control:

Different materials require different temperature conditions for testing. The chosen industrial oven should have a temperature range and control capabilities that match the specific requirements of the materials being tested.

Energy Efficiency:

In an era where sustainability is a key concern, opting for energy-efficient industrial ovens not only reduces the environmental impact but also contributes to cost savings over time.

FAQs About Industrial Ovens:

How do industrial ovens contribute to quality assurance?

Industrial ovens create controlled environments, ensuring consistent testing conditions and contributing to the precision and reliability of results in material testing.

What are the key features to look for in an industrial oven for materials testing?

Critical features include precise temperature control, uniform heating, safety mechanisms, and energy efficiency, all of which contribute to the accuracy of materials testing.

How do industrial ovens enhance the accuracy of test results?

By providing uniform heating and controlled conditions, industrial ovens minimize variables that could impact test results, ensuring that the obtained data is accurate and reliable.

Conclusion:

In the realm of Certified Material Testing Products, industrial ovens emerge as indispensable tools, playing a pivotal role in ensuring the quality and integrity of materials used in various projects. Their ability to provide precise and consistent testing conditions contributes significantly to the accuracy of results, ultimately impacting the safety and durability of structures.